Pettit Vivid Hard SR Ablative Antifouling Bottom Paint

- SKU:

- PET-1261Q.1

-

-

Total Price:

Add to Cart

Pettit Vivid Ablative Antifouling Boat Paint

With bold color and powerful protection, Pettit bottom paint delivers a bright, smooth, hard finish with long-lasting antifouling performance. Multi-season Pettit Vivid bottom paint combines bright, eye-catching pigments with a durable, self-polishing formula that resists marine growth while maintaining fuel efficiency. Ideal for use on fiberglass, aluminum, and wooden hulls, it's perfect for boaters who want both aesthetics and reliability. Designed for both saltwater and freshwater, Vivid offers excellent adhesion and is available in vibrant blue, green, yellow, or red, as well as classic black or white.

A top marine paint brand, Pettit is known for its innovative and high-quality bottom paints. They are committed to providing their customers with the latest in technology in bottom paints. Pettit Vivid brings Pettit bottom paints to a new level. Their paints are widely considered to be some of the best on the market.

Pettit Vivid bottom paint is formulated to have the brightest, most vibrant colors with several color choices as well. Responding to customer requests, Pettit now offers the whitest of white tints in Pettit bottom paints. Pettit Vivid bottom paint is formulated with a hybrid technology that incorporates both the benefits of ablative paints along with hard paints. Pettit Vivid bottom paint dries to a smooth finish and withstands day-to-day use and trailering. Pettit Vivid bottom paint is easy to apply, and Wholesale Marine’s pros recommend that surfaces are primed first.

Key Features:

- Vivid's Hybrid technology offers all the advantages of ablative and hard paints

- Clean, bright colors including true white and black

- Dual-biocides provide excellent multi-season protection

- Excellent for Racing, Trailering, or Rack-Stored Boats

Colors Available: 1261 Blue, 1861 Black, 1661 Red, 1361 Green, 1461 Yellow, 1161 White

Colors can be mixed to achieve a broad spectrum of new bright bottom paint colors. Refer to the color chart for mixing information.

Specifications:

- Finish: Flat

- Solids by Weight: 83%

- Coverage: 440 ft2/gal.

- VOC: 330 grams/liter (max)

- Biocide: Cuprous Thiocyanate - 25.0% | Zinc Pyrithione - 2.80%

Associated Products

- Pettit 120 Brushing Thinner - For thinning in brush and roller applications

- Pettit 121 Spraying Thinner - For thinning in spray applications

- Pettit Protect Epoxy Barrier Coat Primer - Suggested primer - especially for white or light colored applications

How Much Pettit Vivid Bottom Paint Do I Need for My Boat?

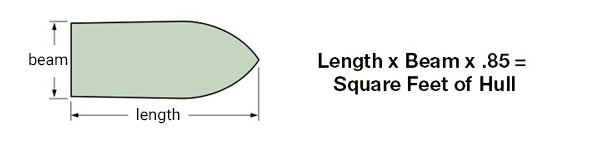

Refer to the chart below to calculate how much vivid paint you will need for your boat.

- Calculate the square footage of the hull to be painted - multiply the length of the hull by the beam then multiply that total by .85

- Divide that number (your square foot total) by the amount of coverage Vivid provides. (440 square foot per gallon). This will give you a one-coat total.

Example: If your boat has a length of 28', and a beam of 8.5', you will multiply 28 x 8.5 x .85 to get your total square footage. The total square footage for this boat is 202.3 square feet. A gallon of Vivid has a coverage of 440 square feet per gallon for one coat, so one gallon will be enough for two coats.

How To Apply Pettit Vivid Bottom Paint

Pettit Vivid bottom paint can be easily applied by brush, roller, or spray. Prior to application, mix paint thoroughly to ensure pigments are evenly dispersed throughout the can. All surfaces must be clean, dry, and properly prepared prior to painting. When rolling, use only a high-quality short nap (maximum 3/16" nap) roller cover. Apply using thin coats; over-application of this product will cause inadequate coating performance.

- Application Method: Brush, roller, airless or conventional spray. When applying by roller use a short nap (3/16 inch maximum) roller cover

- Number of Coats: 1 minimum per season with additional coats for extended service

- Dry Film Thickness: 2 mils (3.1 wet mils)

- Coverage: 440 sq. ft/gal.

- Application Temp: 50°F Min. / 90°F Max.

- Thinner: 120 Brushing Thinner. 121 Spraying Thinner, or 120VOC Thinner

| Temp | To Recoat | To Launch |

| 90°F | 4 HR | 16 HR |

| 70°F | 8 HR | 24 HR |

| 50°F | 16 HR | 48 HR |

*The above dry times are minimums. Vivid may be recoated after the minimum time shown. There is no maximum dry time before launching.

Surface Preparation and Application Systems

Previously Painted Surfaces

- If the previous coating is in good condition:

- Thoroughly sand with 80-grit sandpaper. Solvent clean with Pettit 120 or 120VOC Thinner to remove residue.

- Apply 2 thin coats of Vivid.

- If the previous coating is soft or in poor condition:

- Remove to the bare surface by sanding or using paint remover.

- Proceed with appropriate bare system as described below

Bare Fiberglass

- All bare fiberglass, regardless of age, should be thoroughly cleaned with 92 Bio-Blue Hull Surface Prep or de-waxed several times with Pettit D-95 Dewaxer.

- Proceed with either the Sanding Method or one of the Non-Sanding Methods below:

- Sanding Method:

- After dewaxing, sand thoroughly with 80-grit paper to a dull, frosty finish.

- Rewash the surface with Pettit 120 or 120VOC Thinner to remove residue.

- Apply 2 thin coats of Pettit Vivid

- Non-Sanding Method #1

- Thoroughly clean, de-wax, and etch the surface with Pettit 92 Bio-Blue Hull Surface Prep using a medium Scotch-Brite pad in swirling motion; or wash the fiberglass at least three times using Pettit D95 Dewaxer.

- Apply one thin coat of Pettit 6998 Skip-Sand Primer.

- Apply two thin finish coats of Pettit Vivid bottom paint.

- Non-Sanding Method #2

- Thoroughly clean, de-wax, and etch the surface with Pettit 92 Bio-Blue Hull Surface Prep using a medium Scotch-Brite pad in swirling motion.

- Thoroughly rinse all residue from the surface and let dry.

- Apply one coat of Pettit 4740/4741 H2-Prime Epoxy Primer or Pettit Protect High Build Primer.

- Apply two thin coats of Pettit Vivid.

Barrier Coat

- Fiberglass bottoms potentially can form osmotic blisters within the gelcoat and into the laminate. To render the bottom as water impermeable as possible, prepare the fiberglass surface as mentioned above (sanding method).

- Apply two or three coats of Pettit Protect 4700/4701 Epoxy Primer or Vivid Epoxy Primer 4100/4101.

- Apply two thin coats of Pettit Vivid.

Bare Wood

- Sand the entire surface with 80 grit paper and wash clean with 120 Brushing Thinner.

- Apply a coat of Vivid thinned 25% with 120 Brushing Thinner

- Allow to dry overnight, lightly sand and wipe clean.

- Apply two finish coats of Pettit Vivid.

Bare Aluminum

- For maximum corrosion resistance, sandblast to clean, bright metal.

- Remove sanding residue with clean, dry compressed air or a clean brush.

- Immediately apply 2 coats of Pettit 6627 Tie-Coat Primer.

- Apply 2 thin finish coats of Pettit Vivid Bottom Paint.

Application Tips

- Airless sprayer

- Must be at least 3/4 horsepower

- Use a .017 to .019 spray tip

- Thin Vivid 5% using Pettit 121 Spraying Thinner

- Conventional Air Gun

- Must use a pressure pot with 15 to 20 psi on pot

- Thin product 15% using Pettit 121 Spraying Thinner

- Use a .070 spray tip

- Rolling and Tipping

- Thin Vivid 10% with Pettit 120 Brushing Thinner

- Apply using thin coats using a 1/8" to 3/16" smooth nap roller

- Cover only enough area that can be tipped before the paint film dries

- Tip the surface using a quality natural bristle paint brush in a fore and aft direction

- Burnishing Vivid for a Smooth Racing Finish

- Burnishing can be achieved by using a buffer at 1750 rpms, a wool pad, and a Meguiar's Diamond Cut Compound (M85).

- The low-dusting, low-splatter compound creates an effect similar to applying a finishing glaze.

- Burnishing Vivid with Meguiar's Diamond Cut will give you a porcelain-like racing finish without compromising antifouling performance.

- When burnishing, it is recommended to apply a third coat of Pettit Vivid

![]() Click to Download Pettit Vivid Boat Bottom Paint Application Instructions

Click to Download Pettit Vivid Boat Bottom Paint Application Instructions

California Residents:  WARNING

Cancer and Reproductive Harm -

P65Warnings.ca.gov

WARNING

Cancer and Reproductive Harm -

P65Warnings.ca.gov

Pettit Vivid Hard SR Ablative Antifouling Bottom Paint

- Number of Seasons

- Multi Season

- Anti-Slime Additive

- Anti-Slime

- Is Boat Trailerable

- Trailerable

- Hull Material

- Fiberglass, Steel, Wood

- Water Type

- Brackish Water, Fresh Water, Salt Water

- Fast Ship

- In Stock Ships Today

- Style

- Copper Based

- Type

- Multi Season Hard

- fbt-product

- 216890

- fbt-product

- 226552